Where to Discover the Best Welding Shirts for Maximum Security and Comfort

Where to Discover the Best Welding Shirts for Maximum Security and Comfort

Blog Article

A Comprehensive Guide to Choosing the Right Welding Shirts for Optimum Performance and Protection in Hazardous Workplace

Picking the ideal welding t shirt is not just an issue of convenience; it is a critical choice that impacts both efficiency and safety and security in hazardous atmospheres. Aspects such as fit, material composition, and protective attributes play crucial roles in making certain that a welder remains unharmed while keeping optimum capability. Recognizing these necessary aspects can dramatically affect end results on the job. Yet, the nuances of this choice commonly go ignored. What particular attributes should one prioritize to ensure maximum protection and performance in the field?

Importance of Welding Shirts

Welding t-shirts play an important function in the safety and performance of welders, with the appropriate garment significantly impacting both protection and comfort. In the welding occupation, workers are consistently revealed to extreme heat, triggers, and dangerous materials, making ideal apparel necessary to reduce dangers. A properly designed welding tee shirt can serve as a barrier versus thermal burns and other injuries, thus guarding the welder's skin from dangerous components.

In addition, the textile and fit of welding t-shirts directly affect a welder's capacity to execute jobs efficiently. Loose or improperly fitting tee shirts can grab on devices or obstruct movements, resulting in prospective crashes. Alternatively, shirts that are as well tight may restrict mobility, raising tiredness and reducing total efficiency.

In addition to security problems, convenience continues to be extremely important. A welding tee shirt that allows for breathability while supplying sufficient coverage can improve emphasis and productivity. Selecting top notch welding tee shirts is not simply an issue of choice; it is an important part of a welder's toolkit, making sure both safety and optimum efficiency in tough working problems.

Trick Attributes to Think About

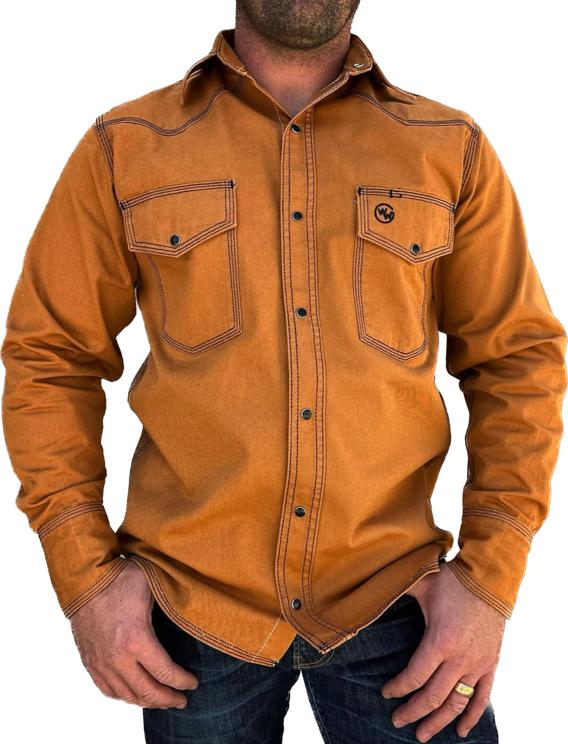

When choosing a welding t shirt, a number of crucial functions should be prioritized to guarantee both safety and convenience. Correct fit is necessary; a shirt that is as well loose may grab on tools, while one that is as well limited can limit motion. Try to find shirts with enhanced seams and long lasting sewing to enhance long life, especially in high-stress locations.

Next, think about the layout aspects, such as collar style and sleeve size. A high collar can supply additional neck security, while long sleeves protect the arms from sparks and warm - Best Welding Shirts. Adjustable cuffs can help safeguard the sleeves, preventing them from rolling up during job

Ventilation is an additional important element. T-shirts with breathable fabrics or mesh panels promote air flow, which can be valuable in warm settings. In addition, the weight of the material matters; larger materials generally supply much better defense but might impede convenience.

Last but not least, analyze security functions such as fire resistance and anti-static buildings. These attributes are important for reducing fire hazards and guaranteeing conformity with security policies. Prioritizing these vital functions will bring about a welding tee shirt that boosts performance while guarding the user.

Finest Materials for Security

Cotton is extensively made use of as a result of its breathability and convenience; however, it needs to be dealt with to improve its flame-resistant properties. Heavyweight cotton or blended products can provide an equilibrium in between comfort and security. Denim, recognized for its durability, provides an added layer of security while keeping flexibility for simplicity of motion.

Sizing and Fit Standards

Picking the proper size and fit for welding shirts is as vital as the products from which they are made. An ill-fitting tee shirt can impede wheelchair, increase fatigue, and position security risks during welding operations. To ensure optimal efficiency, it is necessary to describe the producer's sizing graph, which typically associates measurements with particular dimensions.

When evaluating fit, think about both the body dimensions and the meant use the t shirt. A welding t shirt ought to enable a complete variety of motion-- specifically in the arms and shoulders-- without being exceedingly loose, which might capture on tools or reveal skin to risks. It is advisable to opt for t shirts that include an unwinded fit, as they supply comfort while keeping safety and security criteria.

Additionally, pay attention to the shirt's size; it must cover the torso properly to stop stimulates or liquified steel from getting in. Sleeves must be long enough to make sure insurance coverage while functioning, ideally finishing at the wrist or just past. Lastly, take into consideration the possibility for layering; if the shirt will certainly be used over various other safety equipment, guarantee there is sufficient room for added garments without compromising safety and security.

Maintenance and Care Tips

Appropriate upkeep and care of welding t shirts is critical to extending their life expectancy and guaranteeing recurring security and efficiency. To maintain the stability of these specialized garments, it is necessary to adhere to details treatment guidelines. First, always examine the supplier's label for washing instructions, as various products may have varying requirements.

When cleaning welding shirts, utilize a moderate cleaning agent and refrain from using bleach or fabric softeners, as these can jeopardize the protective high qualities of the textile. It is recommended to wash shirts independently from various other clothing to prevent contamination from lint or fibers that may fire up. Additionally, consider using cool water to preserve the Read More Here material's strength.

After washing, tumble completely pop over to these guys dry on low warm or air dry, as heats can harm the material and influence its protective buildings. Regularly check the shirts for indicators of wear, such as fraying joints or openings, and replace them as needed to keep security requirements.

Conclusion

In verdict, selecting the appropriate welding t-shirt significantly adds to security and efficiency in dangerous workplace. Essential features, including the right materials, fit, and maintenance methods, enhance protection against heat and triggers. With careful consideration of these aspects, welders can make sure ideal performance and resilience in their protective gear. Eventually, a well-chosen welding t-shirt works as an essential component in advertising both security and efficiency in welding procedures.

Report this page